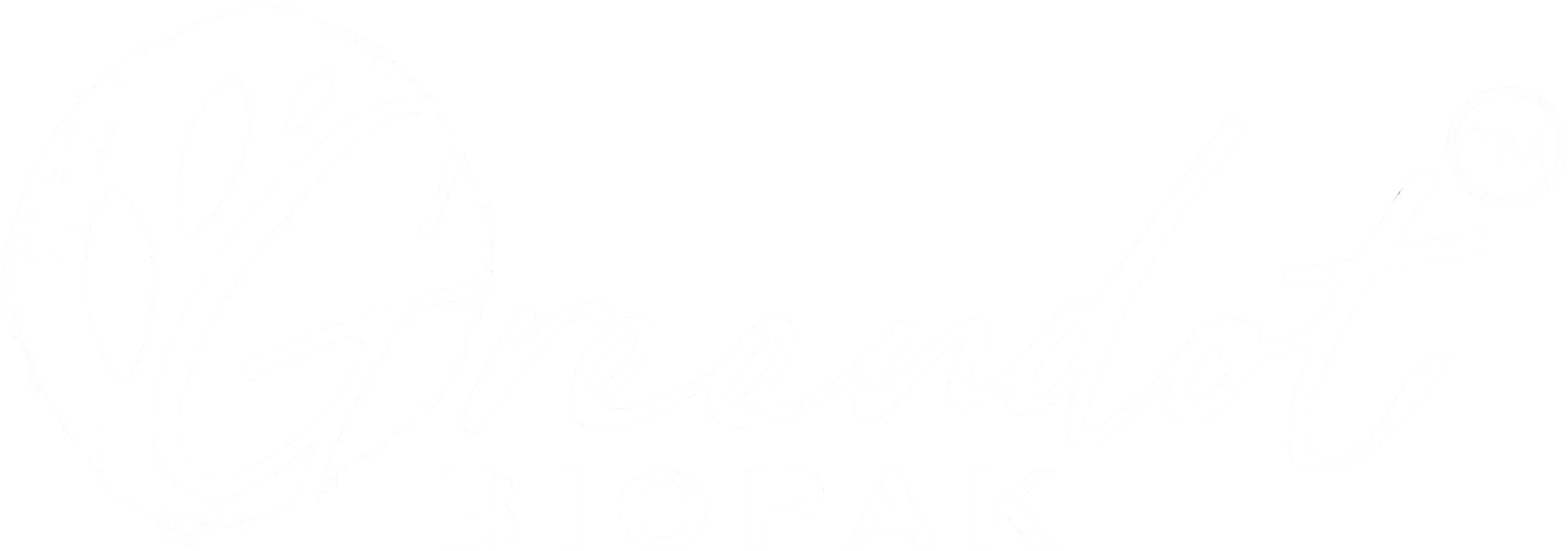

Meat Wrap Cling Film

Meat Wrap Cling Film Manufacturer

Meat Flim characteristics

Maximum Cling

Wraps around porcelain, glass, ceramic, steel, and certain plastic containers to secure food without the inconvenience of film entanglement. It also has good film-to-film clinginess.

Extreme Cold Resistant

Even at subzero temperatures of up to -30 °C (-22 °F), it does not break.

Excellent Breathability

Keeps meat fresher for longer, extending its shelf life.

Crystal Clear Transparency

Food items are packaged with exceptional optical clarity, allowing consumers to see the contents clearly through the packaging material.

Microwave Compatible

The film does not release toxic substances into wrapped food when heated.

No Spillage

The film provides a secure seal for food containers, guaranteeing spill-free storage and preservation.

BPA Free

It is free of the plasticizer bisphenol A (BPA), stabilizers, chlorine, and any other compounds that are detrimental to human health.

100% Recyclable & Eco-Friendly

Polyethylene is easily recycled, without releasing any harmful substances into the environment.

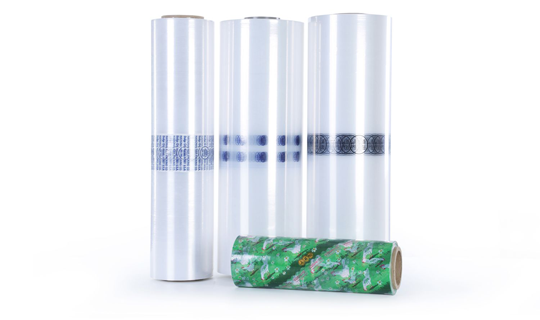

Meat Wrap Film Available in

Shawarma / Doner Film

Shawarma/Doner film possesses functional tackiness, high strength, and outstanding stretchability, as well as exceptional sealing properties, making it ideal for maintaining the freshness and flavor of the shawarma for a longer period of time, even in cold storage circumstances.

Micro-Perforated Film

This film contains micro pores that allow air penetration to keep the rate of breathing constant. Micro-perforation is the process of producing holes in a film with a diameter of 1 mm to 2 mm using a cold, hot needle, or laser.

Printed Film

Printing on film is required by meat makers and packers for brand building and consumer confidence. Using the advanced technique, we can provide printed meat film in up to six colors.

Meat Wrap Film Specification

| Attribute | SI Units | FPS Units |

|---|---|---|

| Width | 280 – 700 mm | 12 – 28 in |

| Length | 500 to 2000 m | 1500 ft to 6000 ft |

| Thickness | 8 – 25 µ | 32 – 100 gauge |

| Core ID | 50 / 76 / 114 / 150 mm or as per requirement | 2 / 3 / 4.5 / 6 in or as per requirement |

Technical Properties

| SI | FPS | ||

|---|---|---|---|

| Tensile Strength | MD | 10-24 MPa | 1500-3500 psi |

| CD | 8-13 MPa | 1200-2000 psi | |

| Elongation | MD | 150-200 % | 150-200 % |

| CD | 350-400 % | 350-400 % | |

| Permeability (OTR) | 35000 cc/m² per 24 hrs | 2260 cc / 100 in² / 24 hrs | |

| WVTR | 115 g/m² (24 hrs) | 7.42 g / 100 in² / 24 hrs | |

| Food Safety Compliance |

Meets the latest food contact regulations as per EU directive no.10/2011 (Ref.2002/72/EEC) |

Meets the latest food contact |

|

Application and Usage

Greendot's Polyfilms has extensive knowledge of the packaging of meat and poultry products. No matter what you're packing—beef, veal, hog, poultry, or lamb—we offer outstanding packaging solutions. In order to help you stay competitive, our first priority is to offer the best packaging solutions that will help you boost dependability and efficiency, cut operational expenses, and eliminate product waste.

The two problems that Greendot Meat Wrap Film successfully overcomes are:

- keeping the meat red for a long time to maintain freshness.

- Maintaining clear packed meat trays so that customers can see through the case-ready pack.

Application of Meat Wrap Film

Meat Tray Overwrapping

Poultry Wrapping

Ground Meat Wrapping

Offal Cut Meat Wrapping

Lean Meat Wrapping

Red Meat Wrapping

We Are Certified

Get Best Price

Scan the QR to call